Nonwoven geotextile fabric has emerged as a vital component in various civil engineering and construction applications, owing to its unique properties and benefits. This innovative material, composed of interlocked fibers rather than weaving, provides enhanced drainage, filtration, and separation, making it an ideal choice for a wide range of projects. As the demand for sustainable and efficient engineering solutions continues to grow, understanding the myriad advantages of nonwoven geotextile fabric becomes increasingly important.

The versatility of nonwoven geotextile fabric means it can be utilized in various applications, including road construction, erosion control, and landscape management. Its ability to improve soil stability, reduce erosion, and facilitate water management makes it an essential material for environmental protection and infrastructure development. In the following sections, we will explore the specific benefits and applications of nonwoven geotextile fabric, illustrating how it plays a crucial role in modern engineering practices. As we delve deeper into this topic, we will showcase why this fabric is not only effective but also a critical component for sustainable development in construction and landscaping.

Nonwoven geotextile fabric is a critical component in the field of civil engineering and environmental management, known for its versatility and effectiveness in various applications. Defined as a permeable textile material made from nonwoven fibers, it functions primarily to separate, filter, reinforce, and protect. The primary types of nonwoven geotextile fabrics include needle-punched, heat-bonded, and spun-bonded fabrics, each offering unique properties suited for specific project requirements. According to the latest market analysis by Research and Markets, the global geotextile market is projected to grow at a compound annual growth rate (CAGR) of 10.5% from 2021 to 2026, driven primarily by the increasing demand for sustainable construction practices.

The applications of nonwoven geotextile fabric are extensive, ranging from road and railway construction to landfill and erosion control. Its ability to provide drainage while preventing soil erosion makes it invaluable for maintaining the integrity of slopes and embankments. Data from the Geosynthetic Research Institute indicates that the use of geotextiles can reduce the need for expensive retaining structures by up to 30%, showcasing their cost-effectiveness in project management. Furthermore, nonwoven fabrics facilitate environmental remediation by filtering contaminants from water and stabilizing soil in sensitive areas, confirming their critical role in modern infrastructure projects.

| Type of Nonwoven Geotextile | Benefits | Common Applications |

|---|---|---|

| Needle-Punched Nonwoven | High strength and durability; excellent drainage properties | Road construction, erosion control, and drainage systems |

| Thermal-Bonded Nonwoven | Good dimensional stability; lightweight | Landfill lining, soil stabilization, and landscaping |

| Meltblown Nonwoven | Highly absorbent; excellent filtration capabilities | Stormwater management, silt fencing, and geocomposite drains |

| Spunbond Nonwoven | UV resistant; durable and strong | Agricultural applications, weed control, and pollution remediation |

Nonwoven geotextile fabrics have emerged as essential materials in civil engineering, owing to their numerous benefits and versatile applications. These fabrics serve crucial functions in soil stabilization, erosion control, and drainage, significantly enhancing the longevity and performance of infrastructure projects. According to a report by the Geo-Institute, the use of nonwoven geotextiles can increase the lifespan of roadways by reducing maintenance costs by up to 30%. This economic advantage stems from the fabric's ability to improve the load-bearing capacity of pavements by distributing stresses more evenly.

Furthermore, nonwoven geotextiles play a vital role in controlling water movement and preventing soil erosion. By allowing water to pass while filtering out fine particles, these fabrics effectively manage groundwater and surface water flow, thus protecting slopes and embankments. A study by the Federal Highway Administration noted that integrating nonwoven geotextiles into drainage systems can reduce sediment transport by over 50%, highlighting their effectiveness in maintaining environmental integrity. Given these compelling benefits, the application of nonwoven geotextile fabrics continues to gain traction in sustainable construction practices, underscoring their value in modern civil engineering projects.

Nonwoven geotextile fabrics are versatile materials that play a crucial role in various construction projects. One of their primary applications is in soil stabilization, where they are used to reinforce soil structures, reducing settlement and enhancing load-bearing capacity. These fabrics create a barrier that separates different soil layers, allowing for better drainage and minimizing erosion. Their ability to manage water and soil pressure makes them ideal for road construction, where they help maintain the integrity of the roadway and extend its lifespan.

Additionally, nonwoven geotextiles are widely employed in drainage systems, particularly in the installation of retaining walls and trenches. By facilitating the flow of water while filtering out sediment, these fabrics protect against clogging and enhance the overall efficiency of the drainage system. In landscaping projects, they are used to prevent weed growth and maintain soil health, providing a sustainable solution that supports plant growth while reducing maintenance efforts. Overall, the adaptability and functionality of nonwoven geotextiles make them an essential component in modern construction and environmental applications.

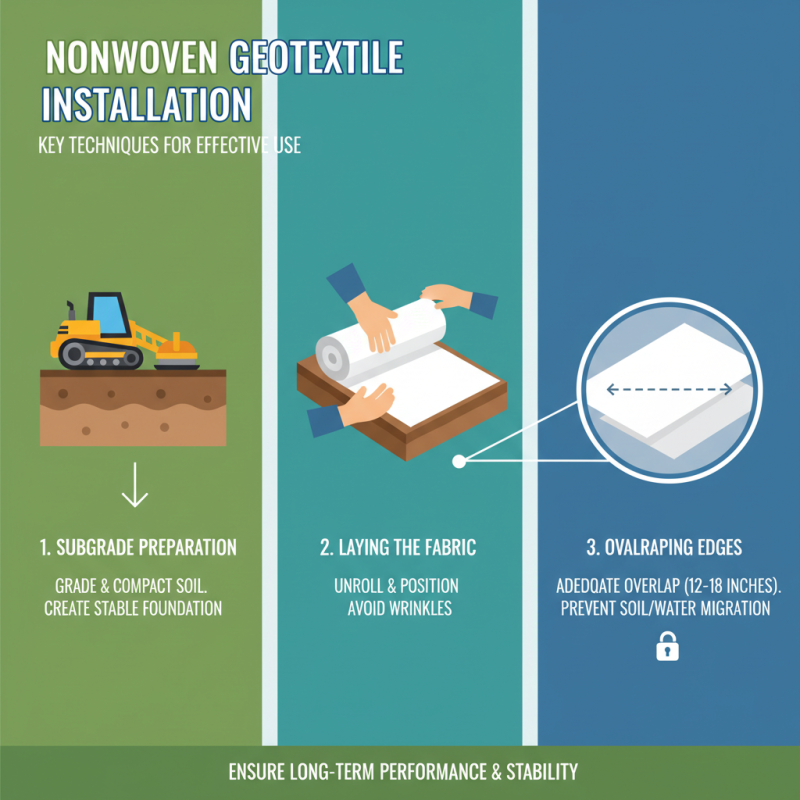

Proper installation techniques are crucial for ensuring the effectiveness of nonwoven geotextile materials in various applications. Before installation, it's vital to prepare the subgrade by carefully grading and compacting the soil to create a stable foundation. This helps to prevent any settlement or shifting that could compromise the geotextile's performance. When laying the fabric, it is essential to overlap the edges adequately to avoid gaps, which could allow soil or water migration, undermining the material's intended function.

Once the geotextile is positioned, securing it properly is important to maintain its integrity during the installation process. Using pins or staples can help anchor the fabric in place, particularly in windy conditions or uneven terrains. It’s essential to minimize the movement of the fabric and ensure it remains flat to achieve optimal performance. After securing the geotextile, it can be covered with aggregate or soil, ensuring that proper compaction is applied to avoid punctures or damage. By following these installation techniques, users can enhance the longevity and effectiveness of nonwoven geotextile applications in various civil engineering and landscaping projects.

As the demand for sustainable construction practices grows, nonwoven geotextile technologies are evolving to meet new environmental challenges. Future trends indicate a shift towards more eco-friendly materials, such as biodegradable options, which can reduce the impact of construction projects on the environment. Innovations in production processes are also emerging, leading to finer fiber technologies that enhance the durability and functionality of geotextiles, allowing for better filtration, separation, and drainage applications.

Tips: When selecting nonwoven geotextiles for your projects, look for products that emphasize recyclability and sustainability, as these choices can contribute significantly to reducing your project’s carbon footprint. Furthermore, investigating the latest advancements in geotextile patterns and designs can provide additional benefits, such as improved soil stabilization and erosion control.

Moreover, digitalization is playing an essential role in the future of nonwoven geotextile technologies. Smart fabrics integrated with sensors can monitor site conditions in real-time, providing critical data on performance and longevity. This trend not only enhances operational efficiency but also helps in making data-driven decisions for future projects.

Tips: Consider staying updated with industry publications and conferences that focus on innovations in geotextile technology. Engaging with thought leaders in the field can provide insights into best practices and emerging trends that can be beneficial for your projects.