In the evolving landscape of civil engineering and environmental management, the choice of materials plays a crucial role in ensuring effective drainage solutions. Among the various options available, plastic culvert pipe has emerged as a favored choice due to its remarkable properties and substantial benefits. According to industry reports, the global plastic pipe market is projected to reach USD 80 billion by 2027, driven significantly by the growing demand for lightweight, durable, and corrosion-resistant materials like plastic culvert pipes. These pipes not only improve water management but also contribute to sustainability efforts by minimizing environmental impact.

The versatility of plastic culvert pipes makes them suitable for a wide range of applications, from agricultural fields to urban drainage systems. Their ability to withstand harsh weather conditions and resist chemical exposure further enhances their utility. Research indicates that the lifecycle cost of plastic piped systems is often lower compared to traditional materials, indicating a long-term economic advantage for projects aiming at effective drainage solutions. As we delve into the top 10 benefits of using plastic culvert pipe, it becomes evident that embracing this innovative solution is not only a smart choice for engineers and contractors but also an environmentally responsible decision for communities worldwide.

The integration of plastic culvert pipes into modern drainage systems brings a multitude of benefits that enhance efficiency and sustainability. One of the primary advantages of using plastic over traditional materials, such as concrete or metal, is its lightweight nature, which simplifies installation and significantly reduces labor costs. According to a report by the American Society of Civil Engineers, the use of plastic culvert pipes can decrease construction time by up to 30%, allowing for quicker project completions without compromising on durability.

Additionally, plastic culvert pipes exhibit superior resistance to corrosion and chemical damage, making them ideal for various environmental conditions. A study published in the Journal of Environmental Engineering highlights that plastic pipes have a lifespan of over 50 years when properly installed, outlasting many conventional options. This longevity not only minimizes the need for frequent replacements but also contributes to lower maintenance costs over time. Furthermore, the use of polyethylene and PVC materials in culverts enhances their ability to handle fluctuating temperatures, reducing the risk of failure and extending the efficacy of drainage systems in diverse climates. As municipalities strive for effective water management solutions, the advantages of plastic culvert pipes position them as a leading choice for future infrastructure projects.

| Benefit | Description | Application Area |

|---|---|---|

| Lightweight | Easier to transport and install compared to traditional materials. | Agricultural fields and rural roads. |

| Corrosion Resistance | Does not rust or corrode, ensuring longevity. | Wetlands and marshy areas. |

| Cost-Effective | Lower material and installation costs reduce overall project expenses. | Infrastructure projects and drainage systems. |

| Durability | Withstands heavy loads and impacts without damage. | Road underpasses and bridges. |

| Flexibility in Design | Available in various shapes and sizes for customized solutions. | Urban development and landscaping. |

| Low Maintenance | Requires little upkeep over its lifespan. | Rural drainage systems. |

| Eco-Friendly | Manufactured from recyclable materials, reducing environmental impact. | Environmental projects and restoration. |

| Resistance to Chemicals | Can handle various chemicals without degradation. | Industrial areas and chemical processing facilities. |

| Enhanced Flow Capacity | Designed for efficient water flow, reducing blockages. | Stormwater management systems. |

When considering drainage solutions, the durability and longevity of plastic culvert pipe materials stand out as major advantages. These pipes are engineered to withstand harsh environmental conditions, making them an ideal choice for both residential and commercial applications. Unlike traditional materials such as concrete or metal, plastic culvert pipes do not corrode or rust, ensuring a longer lifespan and minimal maintenance. Their resistance to chemicals and weather-related wear enhances their reliability, further promoting effective drainage and reducing the need for frequent replacements.

When installing plastic culvert pipes, it's essential to follow specific tips to maximize their lifespan. First, ensure proper installation by following manufacturer guidelines regarding trench depth and pipe alignment. This will prevent issues related to settling or shifting over time. Also, utilize gravel backfill around the pipes to offer additional support and drainage capacity, ultimately reducing the risk of damage. Additionally, regular inspections can help catch any potential issues early, ensuring that your drainage system remains effective for years to come.

Another important consideration is the flexibility of plastic culvert pipes, which allows them to absorb ground movements caused by freeze-thaw cycles and heavy loads. This flexibility not only improves their durability but also presents an advantage in terms of design versatility. Whether it's for rural driveways, agricultural fields, or urban stormwater systems, these pipes adapt well to various applications, offering a long-lasting drainage solution that meets diverse project needs.

Plastic culvert pipes are increasingly being recognized for their cost-effectiveness in various drainage applications. One of the main advantages of using plastic culverts is their lower initial cost compared to traditional materials like concrete or metal. This affordability makes them an attractive option for a wide range of projects, from agricultural drainage systems to municipal infrastructure. Additionally, plastic culverts are lightweight, which reduces transportation costs and makes installation quicker and more straightforward, resulting in significant savings on labor expenses.

Moreover, the durability of plastic culvert pipes contributes to their overall cost-effectiveness. Unlike metal pipes, plastic does not corrode and is resistant to various chemicals and environmental conditions, which minimizes maintenance and replacement costs over time. This longevity means that while the upfront investment may be lower, the long-term financial advantages are substantial. By integrating plastic culverts into drainage solutions, users can achieve reliable performance without compromising their budget, allowing for smarter allocation of resources in both public and private sector projects.

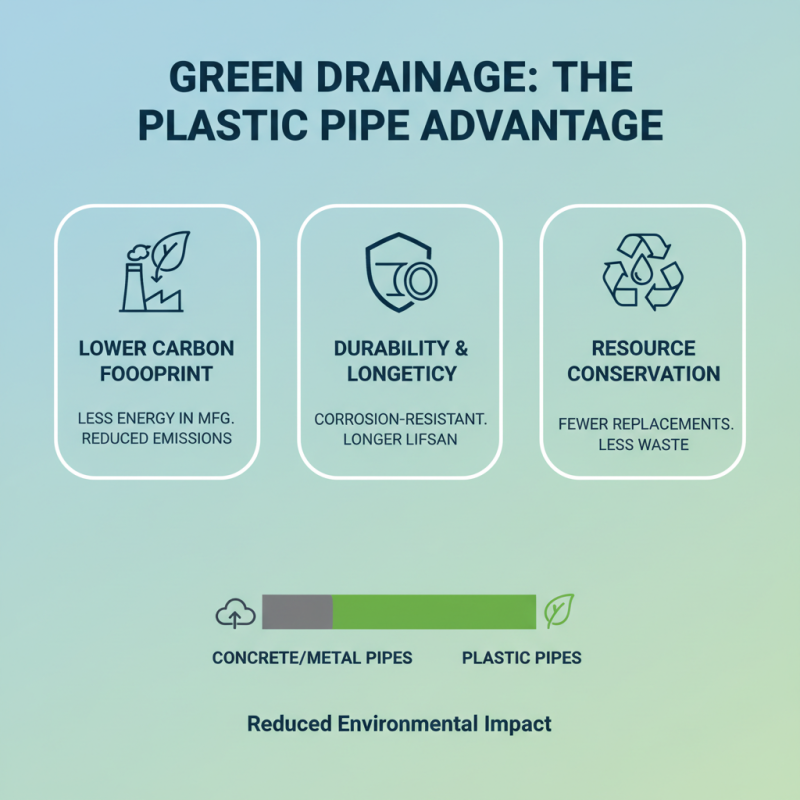

Plastic culvert pipes have gained traction in drainage solutions due to their remarkable environmental benefits. Unlike traditional materials such as concrete or metal, plastic pipes are lightweight and can be produced with a lower carbon footprint. The manufacturing processes for these pipes often require less energy, resulting in reduced greenhouse gas emissions. Additionally, plastic pipes are resistant to corrosion and decay, leading to a longer lifespan and minimizing the need for frequent replacements. This durability not only conserves resources but also decreases waste associated with disposal.

Tips for ensuring environmental responsibility when using plastic culvert pipes include choosing recycled materials whenever possible. Opting for pipes made from recycled plastics can significantly enhance sustainability by reducing the reliance on virgin raw materials. Moreover, proper installation and maintenance can extend the life of the pipes, further diminishing their environmental impact. Regular inspections can identify potential issues early, ensuring that the drainage system operates efficiently and sustainably over time.

The use of plastic culvert pipes can be a sustainable choice for drainage solutions, particularly when considering their minimal environmental impact. By prioritizing eco-friendly practices during installation and maintenance, users can contribute to a healthier planet while enjoying the practical benefits that these pipes offer.

Plastic culvert pipes have gained popularity in drainage solutions due to their ease of installation and low maintenance requirements. Unlike traditional materials, plastic is lightweight, making it easier for workers to maneuver during the installation process. This reduction in labor intensity not only speeds up installation times but also lowers overall project costs. Additionally, the flexibility of plastic culvert pipes allows them to be installed in various configurations, adapting seamlessly to site conditions.

When it comes to maintenance, plastic culvert pipes offer significant advantages. They are resistant to corrosion and chemical damage, which means they require far less upkeep compared to metal alternatives. This durability extends the lifespan of the drainage system, minimizing the need for costly replacements. Moreover, their smooth inner surface reduces the risk of blockages, further decreasing maintenance interventions needed over time.

Tips: When installing plastic culvert pipes, ensure a proper bed of gravel is laid for optimal drainage. Regularly inspect your drainage system to address minor issues before they escalate. Utilizing vegetation along culvert pathways can help filter out debris and maintain clear water flow, ensuring your drainage solution remains effective for years to come.